Introduction to Copper as a Conductor

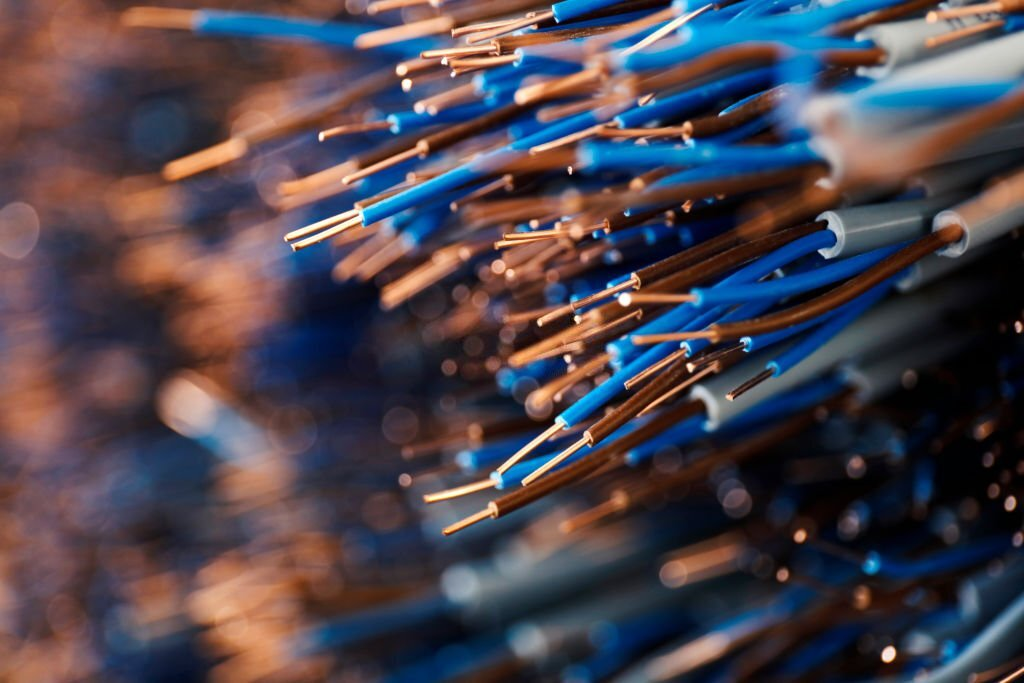

Electrical wiring is the system of conductors and related devices used to carry electricity from a power source to various electrical devices and appliances. It is an essential component of any building or structure, providing the necessary power for lighting, heating, cooling, and other electrical functions. One of the most commonly used materials for electrical wiring is copper.

Copper is a highly conductive metal that has been used for centuries in various applications, including electrical wiring. Its excellent electrical conductivity makes it an ideal choice for transmitting electricity efficiently and reliably. Copper is also known for its ductility and malleability, which allows it to be easily shaped and formed into wires of different sizes and shapes. Additionally, copper has a high resistance to corrosion, ensuring the longevity and durability of electrical wiring systems.

The Properties of Copper that Make it Ideal for Electrical Wiring

1. High conductivity: Copper is one of the most conductive metals, meaning it can easily carry electrical current without significant resistance. This property allows for efficient transmission of electricity, minimizing energy loss and ensuring that electrical devices receive the necessary power.

2. Ductility and malleability: Copper is a highly ductile and malleable metal, which means it can be easily drawn into thin wires and shaped into various forms. This property makes it suitable for manufacturing electrical wires of different sizes and shapes, allowing for flexibility in wiring installations.

3. Resistance to corrosion: Copper has a natural resistance to corrosion, making it highly durable and long-lasting. This property ensures that copper wiring systems can withstand harsh environmental conditions and remain reliable over time.

4. High melting point: Copper has a relatively high melting point compared to other metals, making it resistant to heat and fire. This property is crucial for electrical wiring systems as it helps prevent the risk of electrical fires.

5. Availability and affordability: Copper is abundantly available in nature and is relatively affordable compared to other conductor materials. Its widespread availability and cost-effectiveness make it a popular choice for electrical wiring applications.

The History of Copper in Electrical Wiring

Copper has been used in electrical systems for centuries, dating back to ancient civilizations. The Egyptians, for example, used copper wires to create rudimentary electrical circuits for lighting purposes. However, it was not until the 19th century that copper became widely used in electrical wiring systems.

Advancements in copper wire manufacturing during the Industrial Revolution allowed for the mass production of copper wires, making them more accessible and affordable. Copper’s excellent conductivity and durability made it the preferred choice for electrical wiring installations, replacing other materials such as iron and aluminum.

Copper played a significant role in the development of electricity as a whole. The discovery of electromagnetism by Michael Faraday in the 19th century paved the way for the widespread use of electricity. Copper’s high conductivity and other favorable properties made it an essential component in the construction of generators, transformers, and other electrical devices.

Comparing Copper to Other Conductor Materials

While copper is the most commonly used material for electrical wiring, there are other conductor materials available, each with its own advantages and disadvantages. Some of the notable alternatives to copper include aluminum, gold, and silver.

1. Aluminum: Aluminum is a lightweight metal that is less expensive than copper. It has good conductivity but is not as conductive as copper. Aluminum wires are often used in large-scale electrical installations due to their cost-effectiveness. However, aluminum is less ductile than copper and can be prone to corrosion, making it less suitable for certain applications.

2. Gold: Gold is an excellent conductor of electricity and is highly resistant to corrosion. However, gold is an expensive material, making it impractical for most electrical wiring applications. It is primarily used in specialized industries where its unique properties are required.

3. Silver: Silver is the most conductive metal, surpassing even copper in terms of electrical conductivity. However, silver is significantly more expensive than copper, making it economically unfeasible for most electrical wiring applications. Silver is often used in high-end audio and video equipment where the highest level of conductivity is required.

Each conductor material has its own advantages and disadvantages, and the choice of material depends on factors such as cost, conductivity requirements, and specific application needs.

The Advantages of Copper Wiring in Electrical Systems

1. Efficiency and reliability: Copper’s high conductivity ensures efficient transmission of electricity, minimizing energy loss and ensuring that electrical devices receive the necessary power. This efficiency translates to lower energy costs and improved performance of electrical systems.

2. Safety: Copper’s high melting point and resistance to heat make it a safe choice for electrical wiring systems. It can withstand high temperatures without melting or deforming, reducing the risk of electrical fires.

3. Compatibility with other materials: Copper is compatible with a wide range of materials commonly used in electrical systems, such as insulation materials and connectors. This compatibility allows for easy integration of copper wiring into existing electrical installations.

4. Longevity: Copper is highly durable and resistant to corrosion, ensuring the longevity of electrical wiring systems. Copper wires can last for decades without significant degradation, reducing the need for frequent replacements and maintenance.

The Environmental Impact of Copper Wiring

1. Mining and extraction processes: The extraction of copper from the earth involves mining operations that can have a significant impact on the environment. Mining activities can lead to deforestation, habitat destruction, and water pollution if not properly managed.

2. Recycling and sustainability efforts: Copper is a highly recyclable material, with a recycling rate of over 90%. Recycling copper reduces the need for new mining operations and helps conserve natural resources. Additionally, recycling copper requires less energy compared to extracting it from raw materials, resulting in lower greenhouse gas emissions.

3. Copper’s impact on the environment compared to other materials: While copper mining and extraction processes have environmental impacts, copper’s long lifespan and recyclability make it a more sustainable choice compared to other conductor materials. Materials like aluminum and gold have higher environmental footprints due to their extraction processes and lower recycling rates.

The Future of Copper in Electrical Wiring

1. Advancements in copper wire technology: Ongoing research and development efforts are focused on improving the performance and efficiency of copper wires. New manufacturing techniques and alloy compositions are being explored to enhance conductivity, reduce energy loss, and increase the lifespan of copper wiring systems.

2. Potential for new materials to replace copper: While copper remains the go-to material for electrical wiring, there is ongoing research into alternative conductor materials that could potentially replace copper in the future. These materials include carbon nanotubes, graphene, and other advanced materials with superior conductivity properties.

3. Copper’s role in renewable energy systems: As the demand for renewable energy sources such as solar and wind power continues to grow, copper will play a crucial role in the development of these systems. Copper is used in solar panels, wind turbines, and other renewable energy technologies due to its high conductivity and durability.

Conclusion: Why Copper is the Go-To Material for Electrical Wiring

In conclusion, copper is the preferred material for electrical wiring due to its excellent conductivity, ductility, resistance to corrosion, high melting point, availability, and affordability. Copper has a long history in electrical systems, playing a significant role in the development of electricity as a whole. While there are alternative conductor materials available, copper remains the most widely used due to its favorable properties and cost-effectiveness.

Copper wiring offers numerous advantages, including efficiency, reliability, safety, compatibility with other materials, and longevity. While copper mining and extraction processes have environmental impacts, recycling efforts and sustainability initiatives help mitigate these effects. The future of copper in electrical wiring looks promising, with ongoing advancements in technology and its crucial role in renewable energy systems. Overall, copper’s properties and advantages make it the go-to material for electrical wiring, ensuring the efficient and reliable transmission of electricity in various applications.